Small Business

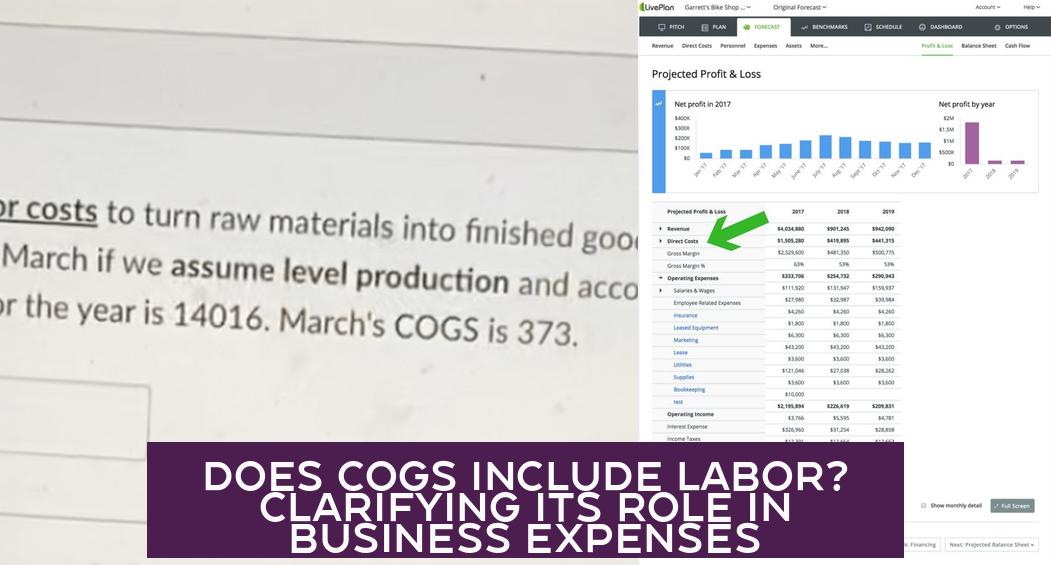

Does COGS Include Labor? Clarifying Its Role in Business Expenses

Does COGS Include Labor?

Cost of goods sold (COGS) includes labor costs that are directly associated with the production of goods. These labor costs typically cover wages paid to employees or contractors who physically manufacture or assemble products. However, labor expenses related to sales, administration, or distribution are excluded from COGS.

Understanding COGS and Labor

COGS represents all direct costs incurred to produce a company’s goods. This includes raw materials, direct labor, and manufacturing overhead. Direct labor means the wages paid to workers who actually create or assemble the product sold.

For example, in an automobile factory, COGS includes the labor costs for assembly line workers putting the cars together. It excludes payroll for sales staff who sell the cars or drivers who distribute them.

What Labor Costs Are Included in COGS?

- Direct Labor: Wages paid to workers directly involved in producing the product. This includes factory workers, machine operators, and assembly line labor.

- Directly Attributable Contractor Costs: Payments to contractors commissioned to work on the product manufacturing, if tied specifically to sales.

- Allocated Labor Costs: Wages for employees whose work is partly involved in production can be proportionally included.

Direct labor is often combined with direct materials and manufacturing overhead to calculate total COGS. Indirect labor, related to supporting roles like supervisors, HR, or administrative staff, is excluded and reported under operating expenses.

What Labor Costs Are Excluded From COGS?

- Sales and Distribution Labor: Payroll for salespeople or delivery drivers does not count as COGS.

- Administrative Salaries: Staff managing HR, finance, or administration expenses fall under operating expenses.

- Owner’s Labor: For small businesses or sole proprietors, the owner’s labor is not included in COGS.

These labor costs contribute to company operations but are unrelated to the physical production of goods. Therefore, they are accounted for separately.

Importance of Direct vs Indirect Labor in COGS

Accurate classification between direct and indirect labor is essential for financial reporting and tax purposes. Only the cost of labor directly engaged in making goods enters COGS. Supervisors or quality assurance employees, whose work supports production but does not create the product, are classified as indirect labor.

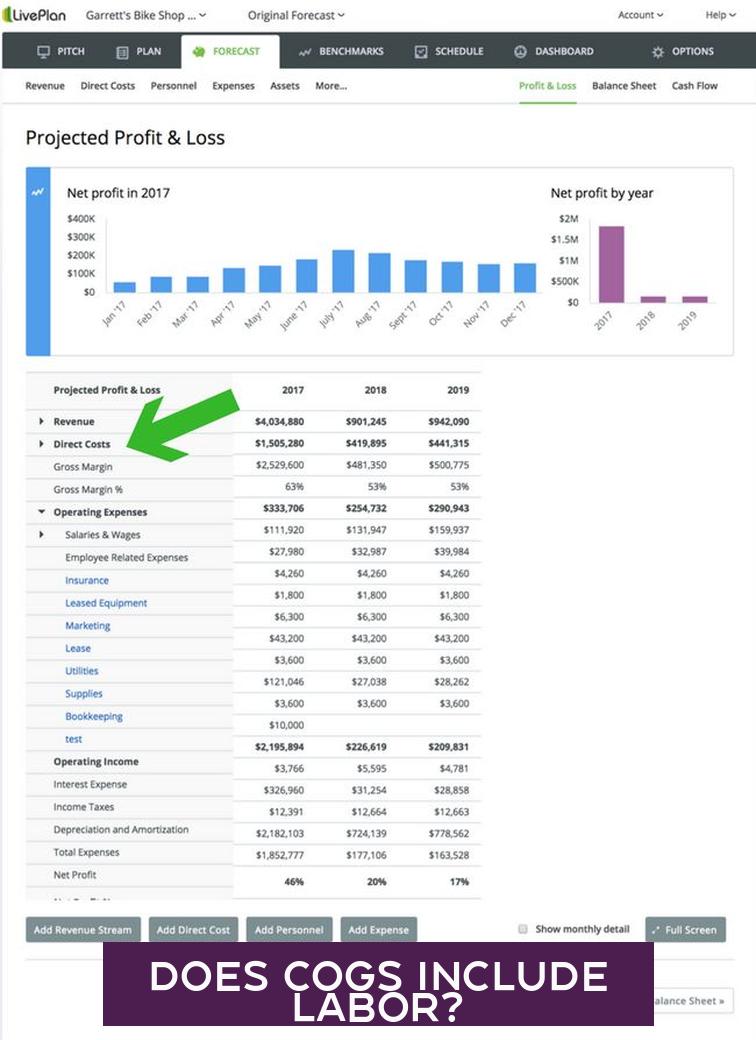

Because COGS directly affects gross profit, misclassifying labor costs can distort a company’s profitability analysis. Companies must allocate labor costs carefully to reflect production efficiency accurately.

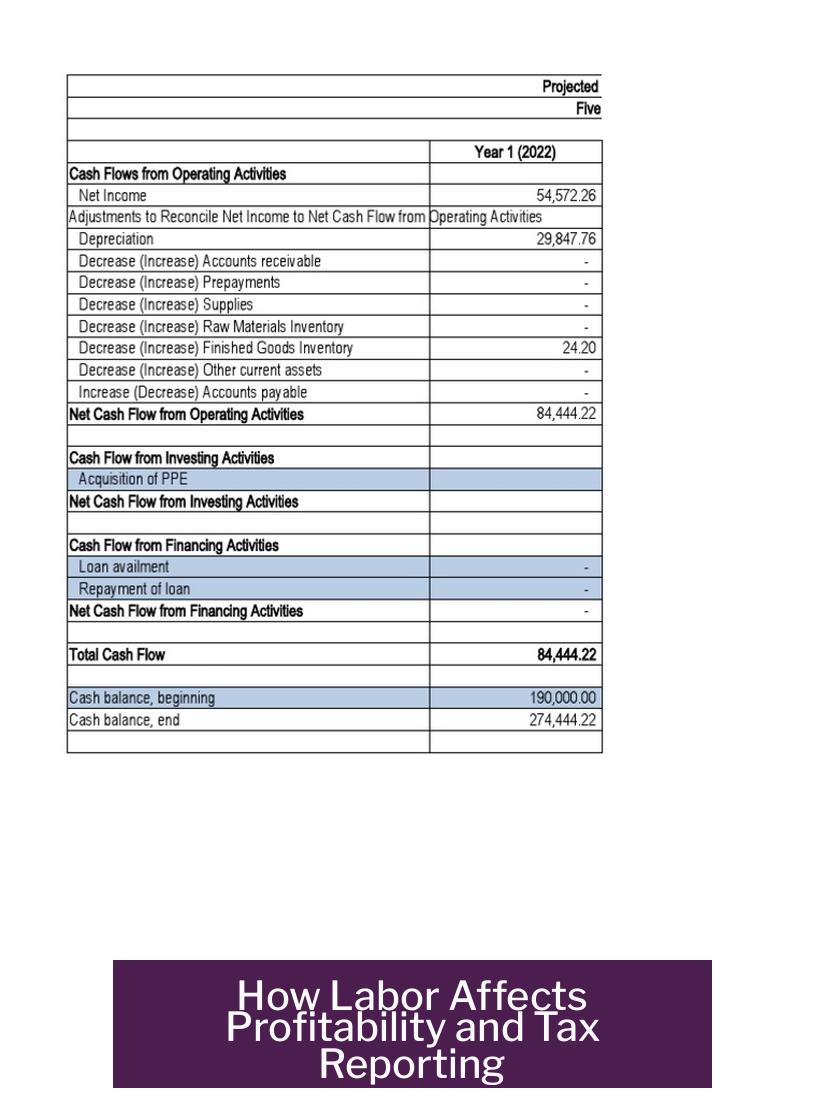

How Labor Affects Profitability and Tax Reporting

Gross profit measures how well a company manages its production costs, including labor. Since COGS reduces revenue to calculate gross profit, labor included in COGS lowers gross profit but properly reflects production costs.

IRS guidelines allow companies to deduct COGS—including direct labor—from revenue when calculating taxable income. Businesses calculate COGS labor costs by multiplying labor hours spent on production by wages or a burdened labor rate, which accounts for additional labor-related expenses like taxes and benefits.

Examples of Labor Included in COGS

- A bakery includes wages paid to bakers as direct labor in COGS. Ingredients like flour and yeast are included as direct materials.

- A car manufacturer includes wages for assembly line workers, plus raw material costs.

- A retailer typically includes cost of inventory and any direct labor for stocking or preparing products but excludes sales staff wages.

Distinguishing Cost of Goods Sold (COGS) from Cost of Sales (COS)

Some businesses use Cost of Sales, which encompasses a broader set of costs, including direct labor and some overhead expenses related to bringing a product to market. COS may include some labor costs excluded in COGS, such as additional production-related overhead.

Key Takeaways

- COGS includes direct labor costs tied to product creation or manufacturing.

- Labor related to sales, distribution, or administrative functions is excluded and classified as operating expenses.

- Properly identifying direct versus indirect labor ensures accurate financial reporting.

- Labor costs included in COGS impact gross profit and taxable income calculations.

- Burdened labor rates help account for total labor costs in COGS.

- Owner’s labor in small businesses is usually excluded from COGS.

Does COGS Include Labor? Unpacking the Mystery Behind Your Business’s Big Expense

Ah, the classic accounting conundrum: does COGS include labor? The short and sweet answer is yes, but—and here’s the kicker—it only includes the direct labor costs. Not the coffee break chats at the water cooler, nor the overtime hours of the relentless HR team. We’re talking about the wages paid to the workers who roll up their sleeves and actually create the product. Let’s dive into the nitty-gritty of why this matters and how this shapes your understanding of your business finances.

Knowing what labor cost belongs in your Cost of Goods Sold (COGS) is essential for clear, efficient financial management. COGS is the backbone that supports gross profit calculations, tax reporting, and business strategy. But juggling which labor costs to throw in and which to leave out sometimes feels like trying to convince a cat to take a bath—tricky but not impossible.

What Exactly Is COGS?

COGS—or Cost of Goods Sold—is a financial metric businesses use to measure the direct costs involved in producing the goods sold during a specific timeframe. This figure impacts your gross profit because it’s subtracted from revenue to reveal how much it costs you to make your sales happen.

Now, here’s where labor wades into the fray: COGS includes the costs of the raw materials that go into your products and the labor directly used in creating those products—not the marketing team’s salaries or the office cleaning crew’s wages.

Direct Labor: The Star Player in Your COGS Lineup

Direct labor is your factory floor warriors, the folks who either assemble your products, operate the machinery, or perform tasks that can be directly attributed to making goods. Consider an automaker: the steel, tires, and glass clearly count as raw materials, but so do the wages of those assembling the cars on the line. That’s direct labor on parade.

In a bakery’s case, the flour and yeast are raw materials, and the bakers mixing and kneading dough? Their wages are direct labor too. This direct labor cost is a major chunk of COGS because it’s intrinsically linked to actually producing the finished product.

What Labor Does NOT Belong in COGS?

If you thought all labor wages eagerly jump into COGS, hold your horses. Not all labor is created equal when it comes to accounting rules. Labor that’s related to sales, distribution, administrative tasks, or general overhead doesn’t slip into COGS.

Take the previous automaker example. The wages paid to the sales team at the dealership or the logistics crew shipping the cars don’t make the cut. They’re part of operating expenses, a.k.a. OPEX, which get a slot elsewhere on your income statement.

Similarly, if you have an administrative assistant or HR manager in your company, their salaries belong to operating expenses, not COGS.

Playing with Labor Types: Direct, Indirect, and “The Others”

When the conversation turns to labor costs, you can divide them into three buckets:

- Direct Labor: Wages to those hands-on with making products.

- Indirect Labor: Employees or contractors who don’t directly work on production but whose efforts support the manufacturing process, like supervisors or maintenance staff.

- Other Labor: Sales, administrative, and other personnel not directly involved in production.

Here’s the subtlety: both direct and some indirect labor can sometimes be included in COGS, especially if indirect labor’s role ties closely to making the product. For example, a factory supervisor’s salary might be classified under manufacturing overhead, which is part of COGS. But, generally speaking, other indirect labor—like HR or general office staff—is excluded.

How Do Labor Costs Impact Profitability?

Because COGS includes labor costs directly tied to production, it influences what’s called gross profit—the difference between revenue and COGS. Efficient management of labor and materials in production means higher gross profit. It’s like trying to bake an exquisite cake without wasting eggs or flour—and without paying bakers to chat all day. Well-managed labor translates to better profitability.

Next time you’re crunching numbers, remember: your labor costs in COGS reflect only those expenses tied directly to creating what you sell. Other labor costs will show up elsewhere.

Cost of Sales (COS) Versus COGS: Why Does It Matter?

Oh, the alphabet soup of accounting! COS (Cost of Sales) sometimes causes confusion because it’s like the cousin of COGS but with a broader social circle. COS can include additional labor-related expenses directly connected with generating revenue. So, whereas COGS sticks to production-related costs, COS might sneak in some extra overhead or delivery labor costs.

However, COS usage varies by company and industry. So, if you see both terms floating around, investigate what each covers in your specific context—not all companies have identical definitions.

Calculating Labor Costs for COGS – The Practical Side

Calculating how much labor to include in COGS isn’t rocket science, but it requires accuracy. Generally, multiply the hours worked on production by your workers’ base pay rate. But that’s not the full story.

Don’t forget the “labor burden”! This includes additional costs like payroll taxes, benefits, and insurance. Including these creates a burdened labor rate, which estimates the true cost of your workforce. Applying a burdened rate gives a more realistic picture of labor costs within COGS.

IRS Guidelines on Labor Inclusion in COGS

The IRS gives businesses the thumbs-up to deduct costs, including direct labor, in calculating taxable income. IRS guidelines specify that only labor directly associated with production or the generation of revenue can be included in COGS.

What about contractors? If your company pays commissions or contractor fees tied to sales, these can sometimes be included in COGS—again, because they are linked directly to your product or revenue generation. But be careful; if the contractors’ work is more administrative or marketing-related, their wages fall outside COGS.

How Small Business Owners Should View Labor Costs in COGS

A quick heads-up to solo entrepreneurs or small-business owners who might be tempted to value the hours they pour into their business as “labor” in COGS: generally, your own labor doesn’t count as a deductible labor cost. Why? Because you aren’t technically “paying” yourself a wage from the business in this context. Instead, your business’s net profit reflects your effort.

But if you hire employees directly producing goods, their wages are direct labor costs and belong in COGS.

A Real-World Example: Knitting Scarves and Counting Costs

Imagine you run a cozy little shop selling hand-knit scarves. You pay three passionate knitters to weave your products. Their wages? Yep, included in direct labor under COGS. The wool, yarn, and embellishments? Those are materials, so naturally, they’re included too.

Now, suppose you also have a receptionist who handles phone calls and schedules. That labor cost is part of operating expenses, not COGS. If one knitter splits time between making scarves and marketing, you can allocate a reasonable portion of their wages to direct labor for COGS.

So, Should You Include Labor in Your COGS? The Final Takeaway

Yes, COGS includes direct labor costs related to production. This means wages paid to employees directly involved in manufacturing or assembling your products count. However, labor related to sales, distribution, administration, or general overhead is excluded, resting comfortably under operating expenses.

Understanding this distinction is not just accountant jargon. It helps you price your products smartly, control costs, and maximize profits. Plus, when tax season rolls around, knowing what counts in COGS makes your filings clearer and lowers the stress.

How Can You Apply This Knowledge?

- Identify who in your team is directly involved in producing goods versus who supports the business in other ways.

- Track hours and wages of direct labor carefully to calculate accurate COGS.

- Separate your operating expenses to avoid mixing costs and muddling your financial reports.

- Consider labor burden in your calculations to get a true reflection of costs.

- Consult IRS resources like Publication 334 and Schedule C instructions to stay compliant.

With these steps, you arm yourself with better insights. Not only do you avoid the financial fog, but you also gain clarity about where your money goes—and where you could tighten the belt.

Have You Ever Wondered How Your Labor Costs Could Change Your Profit Picture?

It’s worth a moment’s reflection. Is your team’s direct labor cost escalating without corresponding sales growth? Are you including the right labor costs in your COGS? Keeping tabs on this could be your secret weapon to boosting efficiency and profitability.

In the end, understanding the labor component of COGS isn’t just an accountant’s puzzle—it’s a practical tool that paints a clearer picture of your business’s financial health. So roll up those sleeves and get your numbers in order. Your accountant—and your bottom line—will thank you for it.

Does COGS include labor costs?

Yes, COGS includes direct labor costs involved in producing goods. This means wages paid to workers who physically make the product. Labor costs unrelated to production, like sales or administration, are excluded.

What types of labor are considered direct labor in COGS?

Direct labor includes wages for employees or contractors who work directly on manufacturing the product. For example, factory line workers assembling goods are counted. Supervisors or sales staff are not included.

Are indirect labor costs part of COGS?

Indirect labor, such as supervisors or maintenance staff related to production, may be included as part of manufacturing overhead in COGS. However, general administrative labor is excluded.

Is labor related to selling or distribution included in COGS?

No, labor expenses for sales, marketing, or shipping finished goods to customers are operating expenses, not included in COGS. Only production-related labor is counted.

How does labor affect gross profit calculation?

Labor costs included in COGS reduce gross profit. Efficient management of labor and materials helps increase gross profit by lowering production costs directly tied to sold goods.

Small Business

Vitamin Business Opportunity: Market Growth, Models, and Profit Strategies

Exploring the Vitamin Business Opportunity

The vitamin business opportunity lies in a rapidly growing global market with high demand, flexible regulatory requirements, and multiple viable business models. Entrepreneurs can capitalize on market expansion, diverse product lines, and evolving consumer needs. This industry offers several profitable avenues backed by solid growth trends and consumer health awareness.

Market Growth and Demand Dynamics

The global dietary supplement market reached a size of $167.5 billion in 2023. Experts predict a steady compound annual growth rate exceeding 7%, potentially pushing the market near $240 billion by 2028. This surge springs primarily from dietary gaps and immune health concerns. Many consumers turn to vitamins to offset nutritional deficiencies and improve wellness.

- Unhealthy diets drive persistent demand for supplements.

- Vitamins appeal to a wide demographic aiming to enhance immunity.

This expansive market creates fertile ground for newcomers and established brands alike.

Regulatory Landscape Advantages

The Dietary Supplement Health and Education Act (DSHEA) of 1994 significantly eased entry barriers by not requiring FDA approval for vitamin products. Instead, the FDA focuses on removing unsafe or illegal supplements after reaching the market. Entrepreneurs benefit from reduced regulatory hurdles but must remain vigilant about compliance to maintain credibility and safety.

| Aspect | Detail |

|---|---|

| FDA Approval | Not mandatory before sales |

| FDA’s Role | Identifies and removes unsafe/illegal products |

| Recommended | Stay updated on supplement laws |

Vitamin Business Ideas and Models

Launching a Private Vitamin Brand

Vitamins do not require FDA approval before sale, easing brand launch processes. Entrepreneurs can develop lines focusing on quality and organic ingredients to align with current trends. Starting with low-demand products reduces competition and can unlock untapped niches.

- Options include gummy vitamins, vitamin-infused drinks, and other innovative formats.

- White-label services simplify brand establishment by providing ready-made formulations.

Subscription Box Business

Regular supplement intake by consumers supports subscription box models that deliver monthly vitamins. Customization based on individual health needs enhances retention. Offering additional services like physician consultations strengthens customer trust.

- Wholesale pricing benefits improve margins.

- Add complementary products like skincare and medical supplies.

Pet Vitamin Products

The pet supplement segment focuses on animal health needs. Livestock and dairy farm operators often purchase supplements in bulk. Animal feed producers incorporate protein powders and vitamins as ingredients.

Supplements Retail Store

Entrepreneurs can operate online or physical specialty stores focusing on dietary supplements. In-person stores provide improved customer service and expert advice. Online dropshipping offers low startup cost and operational flexibility.

- Additional sales include protein snacks, workout gear, and gym apparel.

Steps to Pursue a Vitamin Business Opportunity

- Research: Study the niche, competitors, and compliance requirements. Consult legal experts.

- Planning: Develop a business plan incorporating goals, finances, risk management, and marketing.

- Partnerships: Secure reliable distributors and explore collaborations with gyms or health professionals.

- Marketing: Target audiences via social media, bundle offerings, and distinctive packaging.

- Adaptation: Use customer feedback to refine products and respond to market trends.

Profitability and Industry Potential

Vitamin businesses enjoy profit margins typically ranging from 30% to 50%. The large base of supplement users—about 75% of U.S. adults have taken supplements by 2020—sustains strong demand. The global market’s size and growth potential are compelling incentives for investment.

Main Product Categories

- Multivitamins

- Standalone vitamins

- Probiotics

- Mineral supplements

- Fatty acids

Wholesale Buying and Platform Support

Purchasing vitamins wholesale allows sellers to earn a retail margin. Platforms like BlueCart help connect suppliers with thousands of potential buyers. Automation tools on such platforms streamline order management and improve operational efficiency.

Key Takeaways

- The vitamin market is growing fast and forecasted to reach nearly $240 billion by 2028.

- FDA approval is not required for vitamin sales but regulatory compliance remains critical.

- Business models include private brands, subscription boxes, pet supplements, and retail stores.

- Profit margins typically range from 30% to 50%, with high consumer demand sustaining sales.

- Thorough research, solid planning, partnerships, and adaptable marketing drive success.

- Wholesale buying and digital platforms facilitate supply chain optimization and sales growth.

Unlocking the Vitamin Business Opportunity: Your Guide to a Thriving Supplement Venture

Is jumping into the vitamin business a smart move today? Absolutely. The dietary supplement market is booming, creating multiple doors for entrepreneurs ready to seize the opportunity.

Let’s dive into why this industry shines, what you need to know before you get started, and how you can craft a venture that’s both profitable and sustainable.

Why the Vitamin Business Market Is Buzzing

The vitamin and dietary supplement landscape has transformed dramatically over recent decades. Driven by a worldwide surge in wellness awareness, it’s a goldmine of possibilities. The global market clocked in at a staggering $167.5 billion in 2023 and is forecasted to climb toward $240 billion by 2028, maintaining an impressive growth rate above 7% annually.

Why such high demand? It boils down to people’s health habits. Many consume unbalanced diets or battle weakened immune systems, relying on supplements to fill nutritional gaps. This persistent need keeps the market humming, ensuring steady consumer interest and repeat business.

Navigating the Regulatory Maze

Thinking of launching your vitamin line? Good news: you don’t need FDA approval before selling dietary supplements. The passage of the Dietary Supplement Health and Education Act (DSHEA) in 1994 paved the way for a proliferation of supplement products, significantly loosening regulatory hurdles.

That said, there’s no free pass. The FDA retains authority to remove products deemed unsafe or falsely advertised. So, compliance with labeling and safety regulations remains essential. Hiring a legal expert to steer you through the specifics isn’t just a suggestion—it’s smart business.

Creative Business Models to Consider

The vitamin business isn’t a one-size-fits-all arena. There’s a buffet of options depending on your passion, capital, and market insight.

- Starting Your Own Brand: With no FDA pre-approval required, launching a brand is accessible. Focus on quality and organic ingredients to capture trend-conscious consumers. Starting with lower-demand products can reduce competition and boost your chances. Innovative twists, like gummy vitamins or vitamin-infused beverages, can differentiate your offerings. White-label options simplify brand creation by letting you rebrand existing products.

- Subscription Boxes: Supplements thrive on regular usage. Offering a subscription service taps into this, delivering customized vitamins right to consumers’ doors. Adding perks like free consultations with physicians adds value, making customers stick around. Plus, buying wholesale allows for attractive margins. Throwing in medical supplies or skincare items can widen appeal and increase revenue streams.

- Pet Vitamins: Don’t forget our furry friends! The animal supplement market is sizable and growing. Businesses in animal husbandry or dairy farming look for wholesale supplement supplies to boost livestock health. Similarly, animal feed manufacturers integrate supplements like protein powders into their products. Pet vitamins offer a unique angle in this space.

- Supplement Stores: Whether online or physical, specialty stores cater to customers seeking personalized advice and immediate purchases. Brick-and-mortar outlets shine with their customer service edge. Online stores can leverage dropshipping for lower startup costs and greater flexibility. Selling complementary products such as protein bars, workout gear, and gym apparel can enhance profits.

Five Phases to Launch Your Vitamin Business Successfully

Before you pour cash into bottles and labels, follow these phases for a well-rounded start.

- Research: Comprehensive niche and competitor analysis is your foundation. You also need a thorough understanding of all legal regulations. Hiring a professional lawyer knowledgeable in dietary supplement law is often worth the investment.

- Planning: A detailed business plan guides you. Outline your goals, financial forecasts, marketing strategy, and potential risks. Consider a risk management plan to navigate inevitable bumps.

- Partnerships: Secure reliable distributors early. Collaborate with related businesses like gyms or fitness coaches who can help push your product through consignment deals. Early B2B sales can fund your next steps.

- Marketing: Marketing isn’t just helpful—it’s crucial. Pinpoint your audience, leverage social media, and design eye-catching packaging that complies with the law. Offer bundle deals and discounts to attract customers initially and keep them coming back.

- Adapt and Improve: The market never stands still. Constantly adjust to changing consumer needs and new trends. Customer feedback is your treasure trove for product improvement and customer satisfaction.

What Makes Vitamin Businesses Profitable?

The economics of this industry are enticing. Typical profit margins hover between 30% and 50%. Combine this with broad market demand—statistics show around 75% of U.S. adults tried dietary supplements at least once in 2020—and you’ve got powerful market potential. An expanding audience and high repeat purchase behavior create a rock-solid business foundation.

Core Products to Include in Your Portfolio

Knowing what to sell helps streamline your efforts. The big five product categories generally include:

- Multivitamins

- Standalone vitamins (like Vitamin D or C)

- Probiotics

- Mineral supplements

- Fatty acids (Omega-3, for example)

Hitting these categories covers a wide spectrum of consumer needs and preferences.

Boosting Your Vitamin Venture with Wholesale and Technology

Buying wholesale improves your cost efficiency, allowing you to sell at retail prices competitively. Platforms like BlueCart simplify the supply chain by connecting you with thousands of suppliers and customers. Their tools also automate repetitive tasks, helping you focus on growth rather than admin headaches.

Final Thoughts: Is the Vitamin Business Opportunity Right for You?

With wellness booming and consumers hungry for supplements, it’s an exciting time to jump in. That said, success hinges on smart research, legal savvy, strong partnerships, and savvy marketing. The opportunities stretch from niche organic brands to subscription models, pet supplements, and beyond.

So, is it time to invest your entrepreneurial energy into vitamins? If you’re ready for a blend of health passion, business grit, and customer focus, the market is wide open—and waiting.

What’s your next step?

What makes the vitamin business a growing opportunity?

The dietary supplement market is expanding rapidly. With over $167 billion in sales in 2023 and projected growth of 7% annually, demand for vitamins continues to rise globally.

Can I start a vitamin brand without FDA approval?

Yes, dietary supplements do not require FDA approval before selling. However, the FDA can remove unsafe products. Compliance with other regulations is necessary.

What are some viable vitamin business models?

- Launching a private label brand focusing on quality ingredients.

- Subscription box services offering customized supplements.

- Pet vitamin products for animal health markets.

- Supplements retail stores online or physical locations.

How critical is market research before starting a vitamin business?

Thorough research is essential. Understanding competitors, the target market, and legal regulations helps reduce risks and positions your business better.

What marketing strategies work best for vitamin businesses?

Social media marketing targeting health-conscious consumers is key. Partnering with gyms, fitness trainers, or influencers can boost brand visibility and sales.

Small Business

How Search Engine Marketing Enables Marketers to Display Ads on Websites

How Marketing Lets Marketers Place Ads on Websites with Search Engines

Marketing lets marketers place ads on websites with search engines through Search Engine Marketing (SEM), a paid digital advertising method that helps businesses appear prominently on search engine results pages (SERPs). SEM drives visibility by bidding on relevant keywords and displaying ads when users enter search queries tied to those words. This method uses a pay-per-click (PPC) model where marketers pay only when a user clicks an ad.

Understanding Search Engine Marketing (SEM)

SEM is the process of boosting a brand or product’s visibility in search engines like Google, Bing, or Yahoo through paid ads. It focuses on placing ads in response to user search queries, giving businesses a chance to reach potential customers actively searching for products or services they provide.

- Advertisers bid on keywords related to their offering.

- Ads appear alongside organic search results, typically at the top or bottom.

- SEM strictly involves paid ads, distinguishing it from search engine optimization (SEO), which targets unpaid, organic search rankings.

How SEM Works — The Mechanics

Advertisers enter an ad auction on the search engine platform. Google Ads, for example, evaluates ads based on two main factors: bid amount and Quality Score. Quality Score measures an ad’s relevance to the targeted keyword and overall user experience on the landing page.

Ad placement depends on:

- Keyword Relevance: Ads match the user’s search terms to ensure alignment.

- Bid Value: The amount an advertiser is willing to pay per click influences ad rank.

- Quality Score: Higher scores reduce cost-per-click (CPC) and improve ad position.

Advertisers can target audiences intricately by location, device type, and time of day or week, making SEM flexible and precise.

The Role of SEM in Marketing Strategies

SEM helps businesses show ads to users when they have high intent to purchase. This intent-driven method is beneficial for:

- Small, medium, and large businesses.

- Immediate exposure to potential customers.

- Driving website traffic and increasing leads or sales.

Using SEM, marketers place ads that appear on search engine results pages and other websites affiliated with the search engine’s advertising network, connecting products and services directly with interested users.

Benefits of Using SEM for Advertisement

- Targeted Reach: Ads appear to users based on keywords, geography, device, and time.

- Pay-Per-Click Model: Advertisers pay only when a user clicks an ad, optimizing the ad spend.

- Real-Time Adjustments: Campaigns can be modified or paused instantly based on performance data.

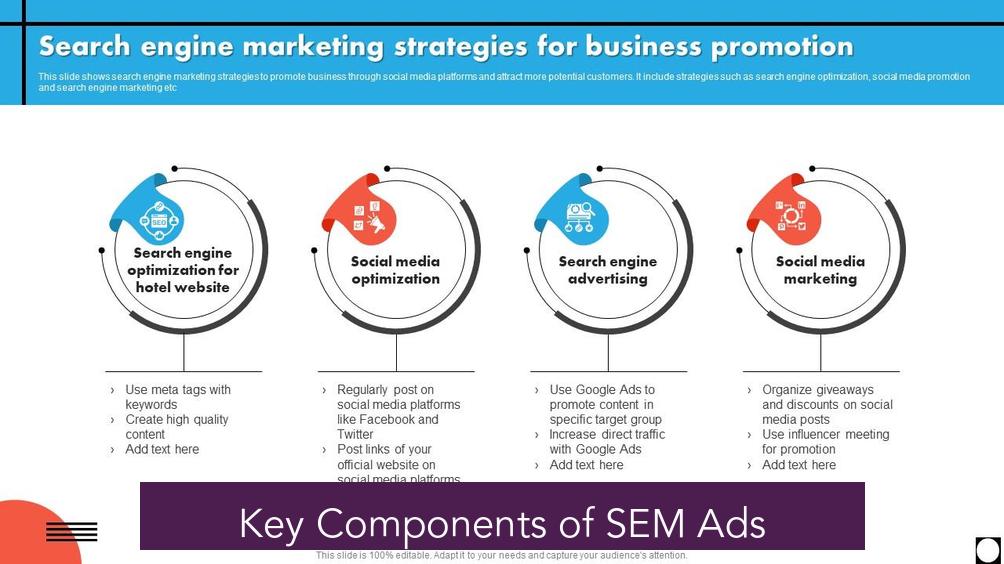

Key Components of SEM Ads

| Component | Description |

|---|---|

| Headline | The clickable blue text users see on search results |

| Description | Short text below the headline providing details |

| Extensions | Additional links or call-to-action buttons |

| Landing Page | The web page users are directed to after clicking the ad |

Proper keyword research is critical for SEM success. Tools such as Semrush, Google Ads Keyword Planner, and Google Trends help marketers identify valuable keywords and analyze competition and trends.

SEM Platforms and Comparison with SEO

- Platforms: Google Ads is the leading platform, with Microsoft Advertising and Yahoo! Native as alternatives.

- SEM vs. SEO: SEM buys ad placements for immediate traffic, while SEO is a longer-term strategy to improve organic rankings without direct payment for placements.

Costs and Budgeting for SEM

SEM budgets vary widely based on goals and industries. Small campaigns might cost around $500 monthly, while larger efforts exceed $10,000. The cost per click ranges from $2 to over $55 depending on keyword competition and industry.

Marketers can adjust spending throughout campaigns to optimize ROI. High competition keywords require higher bids to appear on the first page of search results.

Key Takeaways

- SEM allows businesses to place pay-per-click ads on search engine results and associated websites.

- Advertisers bid on keywords, with ad rank influenced by bid and Quality Score.

- Targeting options include location, device, and time, increasing ad precision.

- SEM provides measurable, flexible campaigns that can be adjusted in real time.

- Cost varies by industry and keyword competitiveness, with budgets ranging from hundreds to thousands monthly.

How Marketing Lets Marketers Place Ads on Websites with Search Engines

Marketing that lets marketers place ads on websites with search engines is known as Search Engine Marketing (SEM). It involves placing paid advertisements on search engines like Google or Bing to help businesses get in front of potential customers when they are actively searching. SEM makes sure ads show up where and when users are looking for products or services, driving traffic and sales in a highly targeted and cost-efficient way.

Now, let’s unravel the nuts and bolts of this fascinating world where ads meet search engines—and why it’s vital for any business hoping to thrive online.

What Exactly Is Search Engine Marketing?

Search Engine Marketing, or SEM, is a strategy that uses paid advertising to boost your visibility on search engine results pages (SERPs). Unlike SEO, which focuses on organic ranking through website optimization, SEM buys prime ad real estate through paid placements.

SEM targets specific keywords that people type into search engines. When you bid on these keywords, your ad could appear above or alongside organic results, shining bright like a lighthouse amid the ocean of search results.

Here’s a quick fact: SEM used to cover both organic and paid strategies, but these days, it’s strictly the paid side of things, where you pay every time a user clicks your ad—known as pay-per-click (PPC).

Why Is SEM a Big Deal for Marketers?

Picture this: customers searching for the exact product or service you offer. SEM helps place your ads precisely at that moment. It’s like waving a flag saying, “Hey, I’m right here!” on the busiest street in your target market.

Search engines have become the primary way people discover new stuff online. Without a strong SEM strategy, your business is hiding in plain sight—or worse, invisible. SEM is crucial because it gets your brand noticed with laser-focused targeting and measurable results.

What’s more, you only pay when someone clicks your ad. That means you’re spending your dollars efficiently, reaching people who already have the intent to buy or learn more.

The Perks of Placing Ads via SEM

SEM offers some compelling advantages that make it a go-to marketing technique:

- Intent-Driven Advertising: Because users are actively searching, your ads meet them with high intent. It’s like catching fish right when they’re hungry instead of casting in empty water.

- Speedy Results: Unlike SEO, which takes time to build organic traction, SEM can drive visible traffic almost immediately. Great for startups or new product launches.

- Real-Time Control: You get instant data on ad performance. If a campaign flops, turn it off instantly. No sunk cost syndrome here.

- Precise Targeting: Beyond keywords, you can target by location, device types, time of day, and even seasons. Imagine your ad popping only when your audience is sipping coffee at 9 AM on a Tuesday.

What’s Inside a Search Ad?

Wonder what an actual search ad looks like? It’s simpler than you think but powerful:

- Headline: The clickable blue title that grabs attention.

- Description: A brief text snippet that highlights your offer or message.

- Extensions: Extra links or actions, like phone calls or location info, inviting more engagement.

- Landing Page: Where users land after clicking—make sure this page seals the deal!

The headline hooks them, the description persuades them, and the landing page closes the deal. This is SEM’s magic pipeline working seamlessly.

How Does SEM Work Behind the Scenes?

Amazing as it sounds, placing these ads isn’t random. SEM follows a precise process:

- Keyword Research: Marketers find popular, relevant search terms their potential customers use.

- Bid on Keywords: Advertisers enter ad auctions, offering money for placements tied to those keywords.

- Quality Score: Google evaluates ads based on relevance and usefulness. The better your ad fits the keyword, the higher the score, which means lower costs per click (CPC).

- Ad Placement: Google picks winners for slots based on Quality Score and bid price.

Think of it like an auction but with a twist: you pay for clicks, not just views. Even winning your bid won’t get you the top spot if your ad is off-topic or poorly constructed.

How Much Does SEM Cost?

Curious about the price tag? SEM budgets can vary as widely as your neighbor’s taste in home décor—from a modest $500 up to $10,000+ per month depending on competition.

Some industries have sky-high costs per click—think legal or insurance sectors where CPC can soar past $50! Others enjoy bargain rates around $2.

The secret sauce? Keyword competitiveness. If everyone wants the same search term, prices skyrocket. Sometimes you’ll spend more to outbid competitors just to sit on page one.

Tools of the Trade: Helping Marketers Play the SEM Game

Luckily, marketers aren’t flying blind into the SEM jungle. A handful of savvy tools make lives easier, smarter, and more cost-efficient:

- Semrush: Offers end-to-end SEM management—from keyword digging to competitor spying.

- Google Ads Keyword Planner: Perfect for kicking off campaigns with targeted keyword ideas.

- Google Trends: See how keyword popularity changes over time to time your campaigns wisely.

These tools equip marketers to pick the right keywords, optimize bids, and analyze performance like seasoned pros.

How Does SEM Differ from SEO?

SEO and SEM often get tangled in the same conversation but they’re fundamentally different beasts:

- SEM: Paid ads that appear at the top or bottom of search results.

- SEO: Techniques to organically rank your website in search engine results, without paying for clicks.

SEO takes patience and effort. It’s like planting a tree and enjoying shade years later. SEM is turning on a searchlight instantly—but it costs per use.

So, which is better? Depends on your goals. Many savvy marketers combine both to maximize reach and balance short-term wins with long-term growth.

Is Google Ads the Same as SEM?

Not quite. Google Ads is the most popular platform for running SEM campaigns but SEM itself refers to the overall strategy and practice of paid search advertising.

Think of SEM as the game, and Google Ads as one of the playing fields. Other platforms exist too, like Microsoft Advertising and Yahoo! Native ads.

FAQs About Marketing on Search Engines

- Is Facebook SEM? No, Facebook is a social media marketing platform. SEM is specific to paid ads on search engines.

- Are SEM tools secure? Good question! Top SEM tools prioritize security with updates, intrusion detection, and data encryption.

Bottom Line: SEM Powers Targeted Website Advertising

So there you have it—marketing that lets marketers place ads on websites with search engines, aka SEM, is a cornerstone of modern digital marketing. It connects businesses to customers actively searching for what they need, using a smart, cost-effective paid advertising approach.

With its precise targeting, real-time measurability, and speedy results, SEM levels the playing field for businesses of all sizes who want to get noticed online. Plus, the combination of powerful tools and flexible budgets means marketers can tailor campaigns to squeeze every drop of value from their ad spend.

Whether you’re a start-up itching to get your name out there fast, or a giant ready to dominate search rankings, SEM offers an unbeatable way to place your ads exactly where your customers are looking. Have you tried SEM in your marketing mix yet? What’s holding you back?

What is search engine marketing (SEM) and how does it help place ads on websites?

SEM is paid advertising that boosts your brand’s presence in search engine results. It lets marketers place ads on search engines like Google, showing products or services when users search relevant keywords.

How does SEM use keywords to target potential customers?

SEM targets specific keywords related to your product or service. Ads appear when users search those words, with costs depending on keyword competitiveness and relevance, measured by Quality Score.

What is the pay-per-click model in SEM advertising?

In SEM, advertisers pay only when someone clicks their ad. This pay-per-click (PPC) system helps control costs and ensures budget is spent on actual customer engagement.

Can SEM ads be targeted by location and device?

Yes, advertisers can specify where, when, and on which devices their ads appear. Campaigns can be geo-targeted, device-targeted, or scheduled for specific times to reach the right audience.

How does SEM allow marketers to measure and adjust their ad campaigns?

SEM platforms provide real-time data on clicks and conversions. Marketers can track ad performance and quickly change or pause campaigns to improve results or cut losses.

Small Business

How to Leave a Google Review for a Business: Step-by-Step Instructions

How to Leave a Review on Google for a Business

Leaving a review on Google for a business involves logging into your Google account, searching for the business, selecting the review option, giving a star rating, and writing your experience before submitting it. This process is simple and fast, enabling customers to share honest feedback that benefits both consumers and businesses.

What Are Google Reviews?

Google reviews provide verified customer opinions in one place, consolidating location, hours, phone details, and user feedback. Over 84% of consumers trust online reviews as much as personal suggestions from friends or family. Positive Google reviews can improve a business’s ranking in search results and attract more customers.

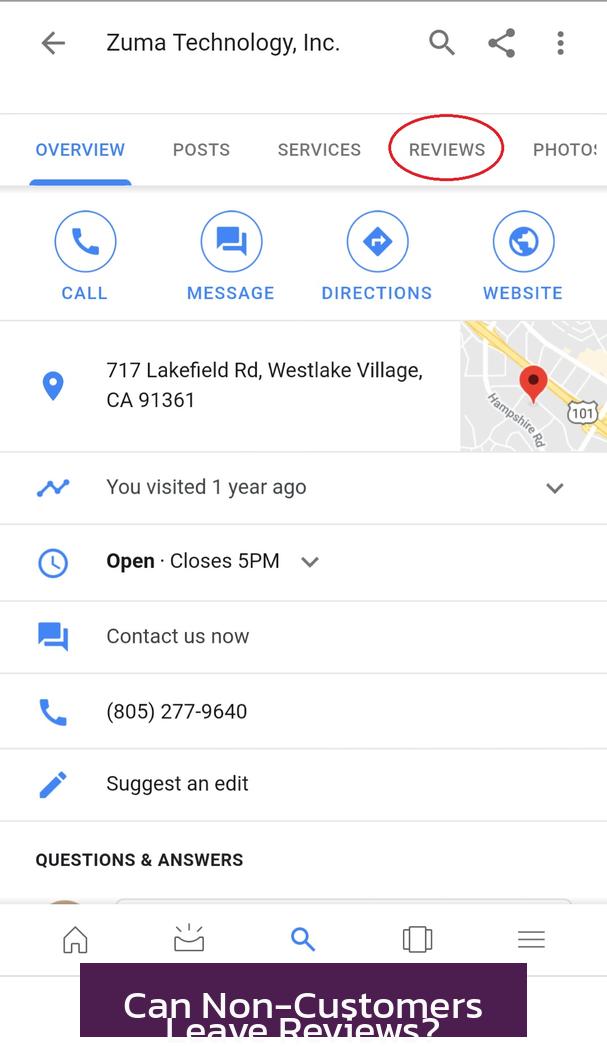

Step-by-Step Guide to Leave a Google Review

- Log in to Your Google Account:

Use the blue login button on the Google homepage’s top right to sign in. Enter your email and password. If you don’t have a Google account, you must create one first. - Find the Business:

Type the company name in the Google search bar or open Google Maps and locate the business. On mobile devices, open the business listing on Google Maps, then tap “Rate & write a report.” - Select “Write a Review”:

On the business profile, you will see existing star ratings and reviews. Click the button labeled “Write a review” to start your own. - Choose a Star Rating:

Rate from 1 star (poor service) to 5 stars (excellent). Each star level reflects your level of satisfaction. - Write Your Review:

Enter your experience or opinion in the text box. Describe your interaction clearly and honestly. - Submit Your Review:

Click “Publish” to post your review publicly on Google.

Important: Reviews written using the same device or network as the business may not display. This restriction helps prevent fake ratings.

Quick Guide Summary

- Log into Google or Google Maps.

- Search for the business.

- Scroll to “Write a Review.”

- Select star rating.

- Write your review.

- Click send or publish.

You’ve now contributed a Google review.

Why Timely Google Reviews Matter

Fast feedback helps businesses adjust quickly to customer needs. Writing a review takes moments unless you choose to write extensively. When customers know how to leave a Google review, businesses can encourage positive feedback effectively.

Additional Insights About Google Reviews

How to Get More Google Reviews

Encourage satisfied customers to write reviews. Ask politely after a good interaction or at purchase points. Incentives are discouraged by Google policies, so focus on genuine requests.

Can Non-Customers Leave Reviews?

Generally, rating a business without using its services is not allowed and may result in removal of the review. For example, you cannot claim a poor haircut if you never visited the salon.

External Experience Reviews by Non-Customers

Non-customers can provide feedback based on indirect interactions, such as phone inquiries or website impressions, as long as the statements are truthful and factual. Examples include commenting on website usability or customer service responsiveness.

Summary: Key Points on Leaving Reviews

- Log into Google account first.

- Search the business on Google or Maps.

- Click “Write a review,” give stars, and write your feedback.

- Publish the review to share it publicly.

- Reviews from non-users based on false claims can be removed.

- Timely direct feedback helps businesses improve.

How to Leave a Review on Google for a Business: A Step-By-Step Guide

Want to share your thoughts about a business on Google but unsure where to start? How to leave a review on Google for a business is straightforward once you learn the steps. Google reviews pack a punch—they combine a business’s info, photos, hours, and feedback all in one place.

With 84% of consumers trusting online reviews as much as personal recommendations, your review can shape someone’s choice. Plus, businesses with positive reviews tend to rank higher on Google Search, getting them more customers (and more reasons for you to write those five stars!). Wondering how to make your review count and actually publish it? Let’s dive in.

Logging In: Your First Step to the Review Stage

First off, you need to be signed into your Google account. Don’t have one? No worries, it’s free and quick to set up. Just click the blue “Login” button in the top right corner of Google’s homepage, enter your email and password (or create a new account), and voila—you’re in.

Think of this as your virtual passport to the land of reviews. Google needs you logged in to ensure your feedback is legit and uniquely tied to a real person. This helps reduce fake reviews, although sometimes it can block genuine ones if, say, the business and reviewer share the same network or device.

Finding the Business You Wish to Review

Once logged in, fire up the search bar. Type the exact name of the business, restaurant, or attraction you want to review. Want to feel a bit more like a detective? Use Google Maps or the Google+ platform (yes, it’s still around in some fashion for reviews).

On a mobile device? Tap the service provider on Google Maps, then hit the button labeled “Rate & write a report.” It’s like knocking on their digital door and being invited inside to share your opinion.

Spotting the Right Spot: Writing Your Review

After searching, you’ll see the business’s profile pop up. Browse existing ratings and comments first for perspective. Found the right place? Click the “Write a review” button.

Here’s where the magic happens. The rating system has two parts:

- Stars: Click on 1 to 5 stars—1 means “not-so-great” and 5 means “wow, highly recommend.”

- Text field: Share a few lines or paragraphs about your experience. You’re the storyteller here. Feel free to mention anything from customer service to ambiance or product quality.

Done? Hit “Publish” to share your thoughts with the world (or at least with anyone who Googles the business). Just a heads-up: Reviews may sometimes fail to display if Google suspects a conflict of interest, like reviews written from the same IP network as the business, but that’s to keep things fair and genuine.

The Quick and Dirty Guide to Posting Your Review

- Open your web browser or Google Maps app on your phone.

- Sign in to your Google account.

- Search for the business you want to review.

- Scroll down to find “Write a Review” next to the Reviews and Add Photo buttons.

- Click “Write a Review”.

- Pick your star rating.

- Jot down your experience or opinion.

- Hit send and bask in the glory of having left your mark!

That’s it. No rocket science involved. Have you ever thought it’d be so simple to make a difference in a business’s online reputation?

Why Bother With Reviews? Why Is Quick Feedback So Important?

Leaving a Google review isn’t just about venting or praising—it’s about shaping real-time customer feedback. This info helps businesses improve and helps future customers make informed choices.

Plus, a speedy review after your visit helps keep your feedback fresh and relevant, which businesses love. It’s probably the easiest and fastest part for you as a reviewer; everything else is just celebrating your new Internet fame.

Frequently Asked Questions: Clearing Up Confusions About Google Reviews

How Can Businesses Get More Google Reviews?

It’s often simple: ask! Businesses that politely encourage happy customers to leave reviews usually see an uptick. Understanding what motivates customers to review helps tailor these requests to feel natural and welcome.

Can Non-Customers Leave Reviews?

Strictly speaking, no. Google expects a reviewer to be a genuine customer to prevent fake or misleading feedback. For example, someone can’t review a haircut if they didn’t get a haircut there—that’s fraudulent.

But Wait, Non-Customers Can Still Say Something?

Yes! If you never bought the product or service but interacted with the business, like asking questions or browsing their website, you can share your external experience. Maybe their website was confusing or an email went unanswered. Your comments must be truthful, but this kind of feedback is allowed.

This adds nuance to reviews, reflecting the full picture of the business beyond just transactions.

Final Thoughts: Your Review Matters

Leaving a review on Google for a business is more than just clicking stars and typing. It’s a powerful act that influences future customers and drives businesses to improve. The process is simple, fast, and gives your voice a platform. Next time you have a memorable experience, good or bad, why not take a minute to share it?

Does the idea of influencing a business’s future sound exciting? Have you ever left a review that changed how others thought about a place? Your next review might just be the one that helps a great business shine or nudges another toward better customer care.

How do I start leaving a Google review for a business?

First, log in to your Google account. If you don’t have one, create a new account. Then, search for the business using Google Search or Google Maps. When you find it, click “Write a review” on its profile.

What steps should I follow to submit my review?

- Select the star rating from 1 to 5.

- Write your opinion in the text field.

- Click the “Publish” button to post your review.

Your review will appear on the business’s Google profile after publishing.

Can I leave a review if I am not a customer of the business?

Non-customers cannot post false claims as reviews. However, they can leave factual feedback about external experience, like website usability or customer service, as long as it is true and accurate.

Why might my Google review not be displayed?

If you use the same device or network linked to the business, your review may not show. This helps prevent fake reviews and keeps the rating trustworthy.

How can a business encourage customers to leave Google reviews?

Businesses can ask satisfied customers directly to leave a review. Knowing why customers leave reviews helps improve the chances of getting positive feedback on Google.

-

Career3 years ago

Career3 years agoWhat is the lowest salary for a pharmacist?

-

Small Business8 months ago

Small Business8 months agoWhat Are the Costs Involved in Registering a Trademark and Key Factors to Consider

-

Career3 years ago

Career3 years agoCustomer success manager career path

-

Career Path3 years ago

Career Path3 years agoIs oilfield services/equipment a good career path

-

Small Business8 months ago

Small Business8 months agoStreaming Music in Malls: Strategies to Enhance Shopper Experience and Boost Business Performance

-

Career3 years ago

Career3 years agoWhat is the highest paying customer service?

-

Customer Service3 years ago

Customer Service3 years agoWhat is the highest paid customer service job?

-

Small Business9 months ago

How to Send eSign Documents: Step-by-Step Guide and Best Tools